Introduction

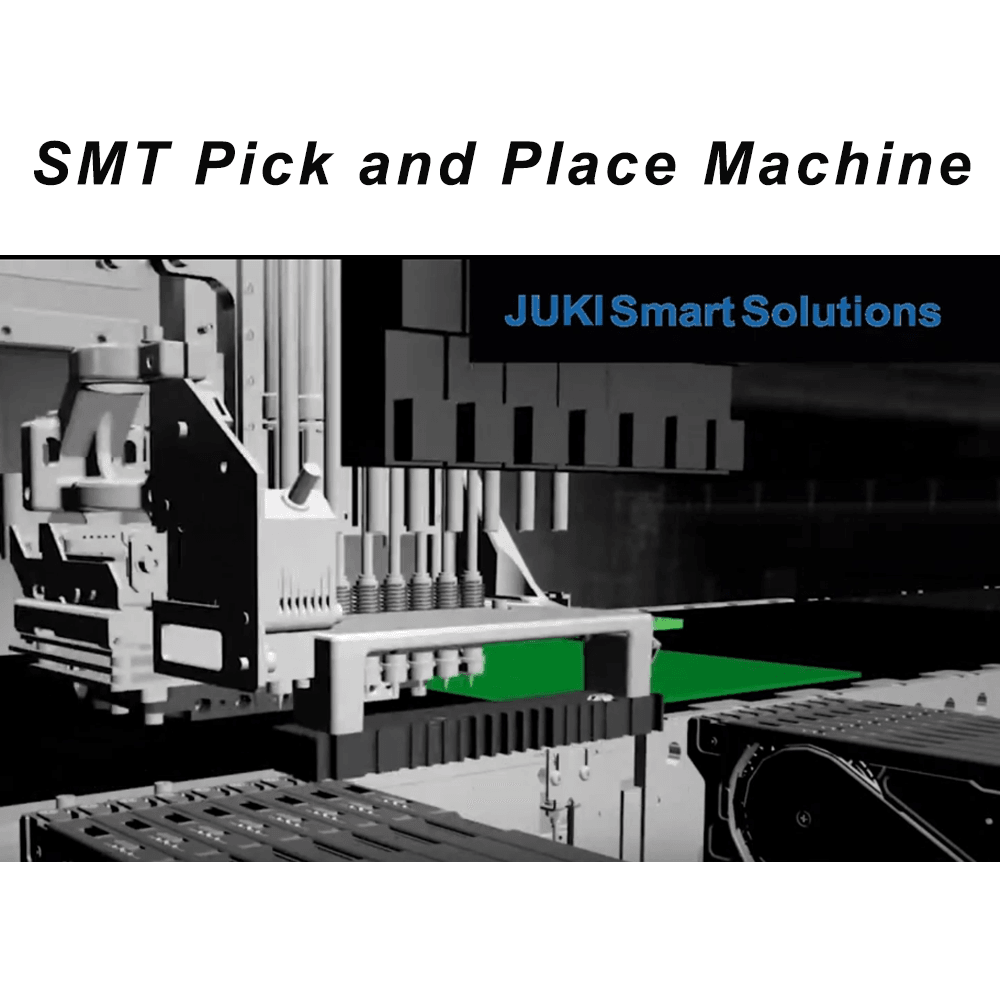

In an era where efficiency and precision reign supreme in manufacturing, the automated pick and place machine has emerged as a game-changer. These machines are revolutionizing how electronic components are assembled onto printed circuit boards (PCBs), significantly enhancing production capabilities. As the demand for faster, more reliable PCB production grows, exploring SMT machines for sale becomes essential for businesses looking to stay competitive.

The Rise of Automated Pick and Place Machines

The rise of automated pick and place machines is largely attributed to advancements in technology that allow for increased speed and accuracy in assembly processes. With the ability to handle thousands of components per hour, these machines have made manual assembly methods nearly obsolete. As industries shift towards automation, the machine pick and place has become a cornerstone of modern PCB production lines.

Exploring SMT Machines for Sale

When searching for SMT machines for sale, it's crucial to understand the variety of options available on the market today. From compact models designed for small-scale operations to high-capacity systems capable of handling large volumes, there's an automated pick and place machine suited for every need. Evaluating factors such as size, speed, and component compatibility will help you find the perfect surface mount machine tailored to your production requirements.

Understanding Their Role in PCB Production

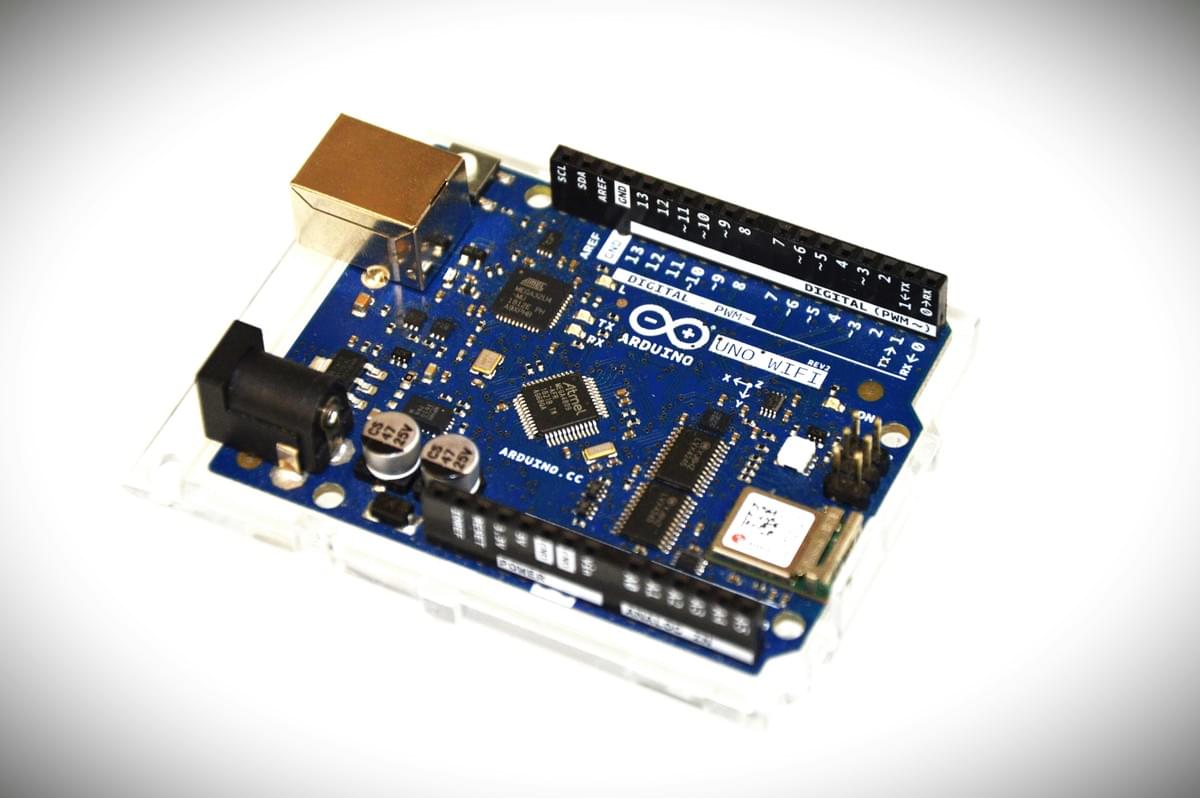

Automated pick and place machines play a vital role in PCB production by ensuring that components are placed accurately on circuit boards with minimal human intervention. This not only speeds up the manufacturing process but also reduces errors that can lead to costly rework or failures down the line. By integrating these advanced smt machines into your workflow, you can enhance overall productivity while maintaining high standards of quality control.

What is an Automated Pick and Place Machine?

Automated pick and place machines are essential tools in modern PCB production, designed to streamline the assembly process of electronic components. These sophisticated machines utilize advanced technology to precisely position various components onto printed circuit boards (PCBs) with speed and accuracy. By automating this crucial step, manufacturers can significantly enhance productivity while minimizing human error.

Overview of Function and Design

At its core, a pick and place machine is engineered to perform a straightforward yet vital function: picking up components from a feeder or tray and placing them onto a PCB at predetermined locations. The design typically incorporates robotic arms equipped with suction cups or grippers that handle various component sizes and shapes. This combination of mechanical precision and intelligent software allows for high-speed operation, making it an indispensable asset in any SMT machine lineup.

Benefits for PCB Production

The benefits of using an automated pick and place machine in PCB production are manifold. First, they drastically reduce assembly time compared to manual methods, allowing for faster turnaround on projects without sacrificing quality. Additionally, these machines offer enhanced accuracy which translates to fewer defects and reworks—ultimately saving both time and money for manufacturers.

Key Features to Look For

When selecting an automated pick and place machine, there are several key features that can make all the difference in your production line's efficiency. Look for machines with flexible component handling capabilities that can accommodate various sizes—from tiny chips to larger connectors—without needing extensive adjustments. Additionally, advanced vision systems are crucial; they ensure precise placement by verifying the correct orientation of components before they're secured onto the PCB.

Top SMT Machines in the Market

When it comes to choosing an automated pick and place machine, the market is brimming with options that cater to diverse needs in PCB production. The right pick and place machine can significantly enhance efficiency and accuracy, making it essential to know which models stand out among the rest. This section will explore some of the best-selling SMT machines available today, comparing their specifications and highlighting what makes them top contenders.

Best Sellers and Their Specifications

Among the best sellers in the realm of surface mount machines is the XYZ 1230 model, which boasts a remarkable speed of 5,000 components per hour. This automated pick and place machine features a user-friendly interface and advanced vision systems that ensure precise placement on PCBs. Another popular option is the ABC Pro SMT-3000, known for its versatility; it can handle various component sizes while maintaining high accuracy levels.

The DEF-400 series has also gained traction due to its robust construction and reliability, making it a favorite for high-volume production environments. With a compact design that fits easily into tight spaces, this machine is perfect for manufacturers looking to optimize their workflow without sacrificing quality. Each of these machines showcases unique specifications tailored for specific production needs within PCB manufacturing.

Comparison of Popular Brands

When comparing popular brands in the automated pick and place market, it's crucial to consider factors like performance, durability, and customer support. For instance, XYZ machines are renowned for their cutting-edge technology but often come with a higher price tag than competitors like ABC or DEF brands. However, many users argue that investing in XYZ results in lower long-term costs due to reduced maintenance issues.

ABC’s offerings are typically more budget-friendly while still delivering reliable performance; they strike an excellent balance between cost-effectiveness and functionality. Meanwhile, DEF machines are celebrated for their ease of use—ideal for businesses new to SMT technology or those scaling operations quickly without extensive training requirements. Ultimately, your choice will depend on your specific needs regarding budget constraints versus desired capabilities.

Recommended Automated Machines

For those venturing into PCB production or looking to upgrade existing setups, several automated pick and place machines come highly recommended by industry professionals. The XYZ 1230 remains at the top of many lists due to its unmatched speed combined with precision—a must-have for any serious manufacturer aiming at high output rates without compromising quality standards.

Additionally, consider investing in the ABC Pro SMT-3000 if you're seeking flexibility across various component types; this machine's adaptability makes it suitable for both small runs and larger-scale productions alike. Lastly, if you prioritize ease of operation alongside reliability during peak production times, then opting for DEF-400 could be your best bet—its intuitive design ensures minimal downtime even when handling complex tasks efficiently.

How to Choose the Right Machine

Selecting the right automated pick and place machine can be a daunting task, especially with so many options available in the market. It’s important to align your choice with your specific production needs, budget constraints, and desired features. This section will guide you through assessing your requirements, understanding financial implications, and exploring customization options offered by Bensun Technology.

Assessing Your Production Needs

When it comes to choosing a machine pick and place for PCB production, understanding your production needs is paramount. Start by evaluating the volume of boards you plan to produce and the complexity of the components involved; this will help you determine whether a basic surface mount machine or a more advanced SMT machine is required. Additionally, consider factors such as speed, accuracy, and flexibility—these aspects can significantly impact your overall efficiency in PCB production.

For instance, if you're working with intricate designs or high-density boards, investing in a sophisticated automated pick and place machine with advanced vision systems may be beneficial. On the other hand, if you're just starting out or handling lower volumes of simpler assemblies, a more budget-friendly option might suffice. Ultimately, aligning your choice with these considerations will ensure that you select an SMT machine that meets both current demands and future growth potential.

The Importance of Budget and ROI

Budgeting for an automated pick and place machine is not just about considering upfront costs; it’s also crucial to evaluate long-term return on investment (ROI). A well-chosen SMT machine can dramatically increase productivity while reducing labor costs over time—making it essential to think beyond initial expenses. Calculate potential savings by analyzing how much time each cycle saves compared to manual assembly processes.

Moreover, consider maintenance costs associated with different machines; some models may require more frequent servicing than others. By factoring in these elements alongside expected output increases from automation in PCB production processes, you’ll be better equipped to make an informed decision that balances both affordability and profitability.

Customization Options with Bensun Technology

Bensun Technology stands out by offering extensive customization options for their automated pick and place machines tailored specifically for diverse manufacturing needs. Whether you're looking for modifications in feeder types or adjustments in placement accuracy settings on your surface mount machine, they have solutions designed just for you! This level of customization ensures that your SMT machines are perfectly aligned with your unique operational requirements.

Additionally, Bensun Technology provides support throughout the customization process—from initial consultation through installation—to ensure that every aspect meets industry standards while enhancing productivity levels within PCB production lines. With their expertise at hand combined with cutting-edge technology features built into their machines smt offerings , users can expect improved efficiency without compromising quality.

Understanding Machine Pick and Place Technology

In the realm of PCB production, understanding the technology behind automated pick and place machines is crucial for optimizing efficiency and precision. These machines are designed to streamline the assembly process, ensuring that components are accurately placed on printed circuit boards (PCBs). By delving into the mechanisms, vision systems, and advancements associated with SMT machines, manufacturers can make informed decisions about their production capabilities.

Mechanisms Behind SMT Machines

The core of any pick and place machine lies in its intricate mechanisms that facilitate component handling and placement. These machines typically employ a combination of robotic arms, suction cups, or grippers to pick up surface mount components from trays or reels. Once a component is secured, the machine’s precise positioning system ensures it is accurately placed onto the PCB in mere seconds—an essential feature for high-speed production lines.

Another critical aspect of these mechanisms is their ability to adapt to various component sizes and shapes. Modern automated pick and place machines can handle everything from tiny resistors to larger integrated circuits with ease. This versatility makes them indispensable in PCB production environments where diverse product lines are common.

The Role of Vision Systems

Vision systems play an integral role in enhancing the accuracy of machine pick and place operations. Equipped with high-resolution cameras, these systems allow SMT machines to identify components on trays or reels before they are picked up. This capability minimizes errors by ensuring that only correctly oriented parts are selected for placement on PCBs.

Moreover, vision systems continuously verify component placement during production runs. If a part is misaligned or incorrectly placed, the system can alert operators or automatically adjust to rectify the issue—saving time and reducing waste in PCB manufacturing processes. The integration of advanced vision technology elevates automated pick and place machines beyond simple mechanical devices into sophisticated tools capable of maintaining quality control.

Advancements in Surface Mount Technology

The evolution of surface mount technology (SMT) has led to significant advancements in automated pick and place machinery over recent years. Innovations such as improved software algorithms enable smarter decision-making during assembly processes, allowing for real-time adjustments based on varying production demands. Additionally, enhancements in machine speed have resulted from better mechanical designs and faster processing capabilities.

Another noteworthy advancement includes increased connectivity options within SMT machines—enabling seamless integration with other manufacturing equipment through Industry 4.0 principles. This connectivity allows for data sharing across platforms that can optimize entire production lines based on real-time analytics from multiple sources. As these technologies continue to develop, investing in an updated automated pick and place machine becomes increasingly essential for staying competitive within the electronics industry.

Maintenance Tips for Your SMT Machine

Maintaining your automated pick and place machine is crucial to ensure optimal performance and longevity. Regular upkeep not only enhances the efficiency of your SMT machines but also minimizes unexpected downtimes that can disrupt PCB production. Here are some essential tips to keep your machine in top shape.

Routine Checks and Cleaning

Routine checks are vital for the longevity of any pick and place machine. Start by inspecting the nozzles, feeders, and belts for wear and tear; these components often bear the brunt of daily use in a busy production environment. Additionally, regular cleaning of dust and debris from the surface mount machine will prevent contamination that could affect precision during assembly.

Don't forget to check alignment settings periodically; even minor misalignments can lead to significant errors in PCB production. Keeping a maintenance log can help track these routine checks, ensuring nothing falls through the cracks. A clean machine is a happy machine, so make this part of your standard operating procedures!

Troubleshooting Common Issues

Even with proper maintenance, issues can arise with your automated pick and place machine. One common problem is mispicks or missed components; this may be caused by worn-out nozzles or incorrect feeder settings. When troubleshooting such issues, start with a thorough inspection of all moving parts to identify any signs of damage or misalignment.

Another frequent challenge is software glitches that may disrupt the operation of your SMT machines. In such cases, rebooting the system or consulting user manuals can often resolve minor bugs quickly. However, if problems persist, it might indicate deeper issues requiring professional intervention.

When to Call in Professionals

While routine maintenance may be manageable on your own, certain situations call for expert assistance with your surface mount machines. If you encounter persistent errors or significant mechanical failures that you can't diagnose yourself, it's time to bring in professionals who specialize in automated pick and place machines. They have the expertise required to perform complex repairs safely without risking further damage.

Additionally, consider professional servicing if you notice a decline in production speed or quality over time; these could be signs that more extensive repairs are needed beyond basic troubleshooting efforts. Remember: investing in professional help can save you from costly downtime later on!

Conclusion

In conclusion, investing in an automated pick and place machine is a strategic move that can significantly enhance the efficiency and accuracy of your PCB production processes. These machines not only streamline operations but also reduce labor costs, allowing businesses to allocate resources more effectively. With advancements in technology, the capabilities of pick and place machines continue to evolve, making them indispensable tools in modern manufacturing.

Benefits of Investing in Pick and Place Machines

The benefits of integrating a pick and place machine into your production line are manifold. First and foremost, these machines offer unparalleled precision when placing components on PCBs, minimizing errors that can lead to costly reworks. Additionally, automated pick and place machines boost production speed dramatically—what once took hours can now be accomplished in mere minutes, giving your business a competitive edge.

Moreover, investing in a surface mount machine reduces the need for extensive manual labor, which not only cuts down on operational costs but also mitigates the risk of human error. As you scale up your operations or diversify your product range, having an SMT machine allows for flexibility without compromising quality or output volume. In essence, these machines are not just an expense; they are an investment that pays dividends over time.

Future Trends in SMT Technology

The future of SMT technology looks promising as innovations continue to emerge at a rapid pace. One significant trend is the integration of artificial intelligence into automated pick and place machines, enhancing their ability to adapt to different tasks with minimal downtime. This means that future machines could learn from each job they perform, optimizing their processes for even greater efficiency.

Another trend involves the development of smaller yet more powerful SMT machines capable of handling increasingly complex circuit boards packed with components. This miniaturization aligns with the growing demand for compact electronic devices across various industries—from consumer electronics to automotive applications. As these trends unfold, manufacturers who stay ahead by adopting cutting-edge technologies will undoubtedly reap substantial rewards.

Why Choose Bensun Technology for Your Needs

When it comes to selecting a provider for your machine pick and place needs, Bensun Technology stands out as a top choice among industry leaders. Their commitment to quality ensures that every surface mount machine they produce meets rigorous standards while offering exceptional performance tailored to diverse production environments. With customizable options available through Bensun Technology, you can find solutions specifically designed for your unique requirements.

Furthermore, Bensun’s customer support is second to none; they provide extensive training resources along with responsive service teams ready to assist whenever needed. By choosing Bensun Technology as your partner in PCB production machinery, you're not just acquiring equipment; you're investing in a relationship built on trust and expertise that will help drive your success forward.