Introduction

In today's technology-driven world, understanding the electronic PCB assembly processes is essential for anyone involved in electronics manufacturing. This intricate process not only involves assembling printed circuit boards (PCBs) but also encompasses a variety of techniques and technologies that ensure functionality and reliability of electronic devices. As we delve deeper into this topic, we'll explore critical questions such as What is the assembly of PCB? and Who is the manufacturer of PCB assembly in China? to illuminate the significance of this industry.

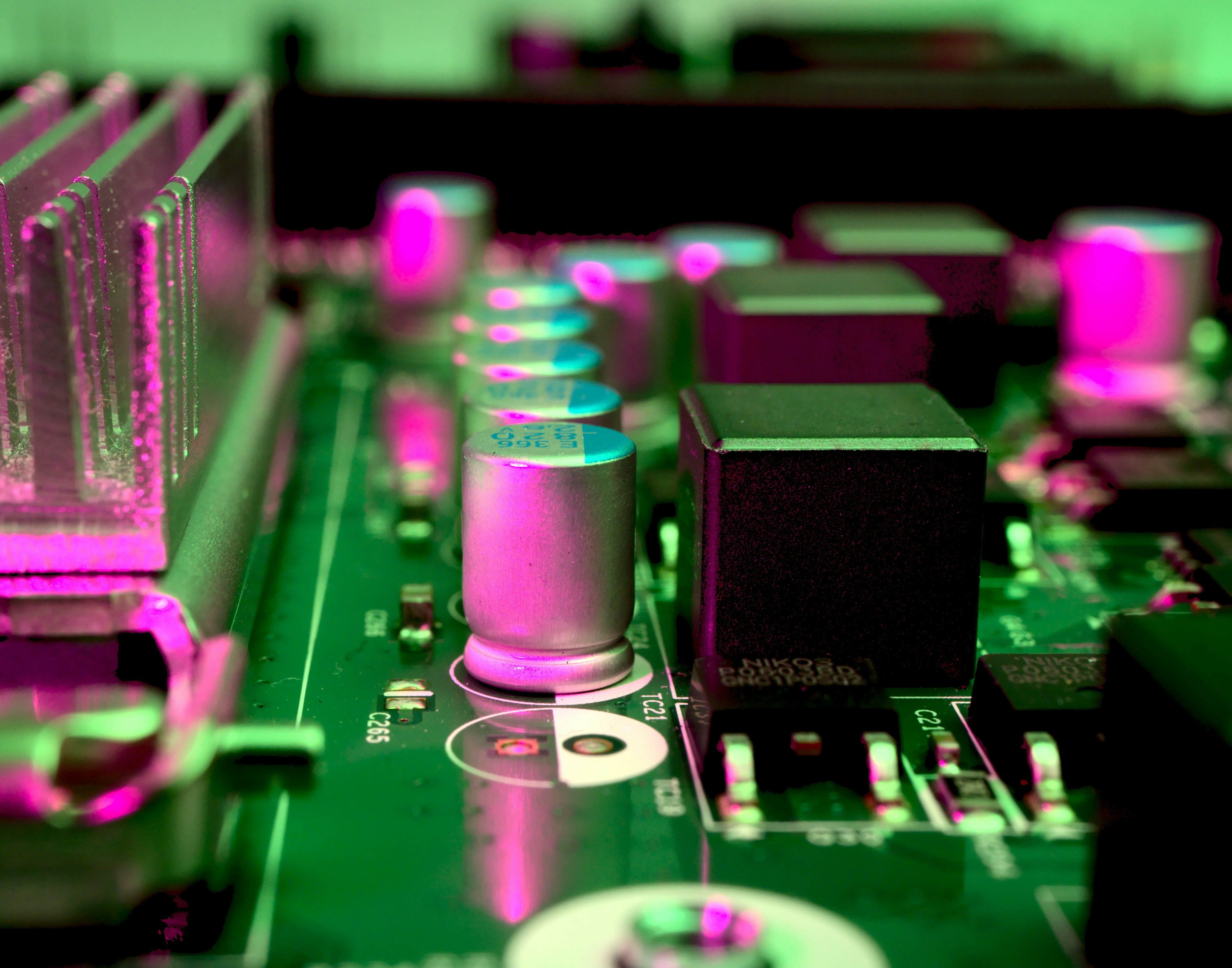

Explore Electronic PCB Assembly Processes

The electronic PCB assembly process is a multifaceted journey that transforms raw materials into fully functional electronic products. It includes several stages, from design and prototyping to actual assembly and testing, each requiring precision and expertise. By exploring these processes, we can better appreciate how they contribute to the final product's quality and performance.

Importance of Understanding PCB Assembly

Understanding PCB assembly is crucial for manufacturers, engineers, and even consumers who rely on high-quality electronics in their daily lives. A solid grasp of what goes into electronic PCB assembly helps stakeholders make informed decisions regarding production methods, component selection, and potential partnerships with manufacturers like Bensun Technology. Moreover, recognizing the nuances between different types of assemblies—such as SMT PCB assembly—can significantly impact project outcomes.

Overview of the PCB Assembly Lifecycle

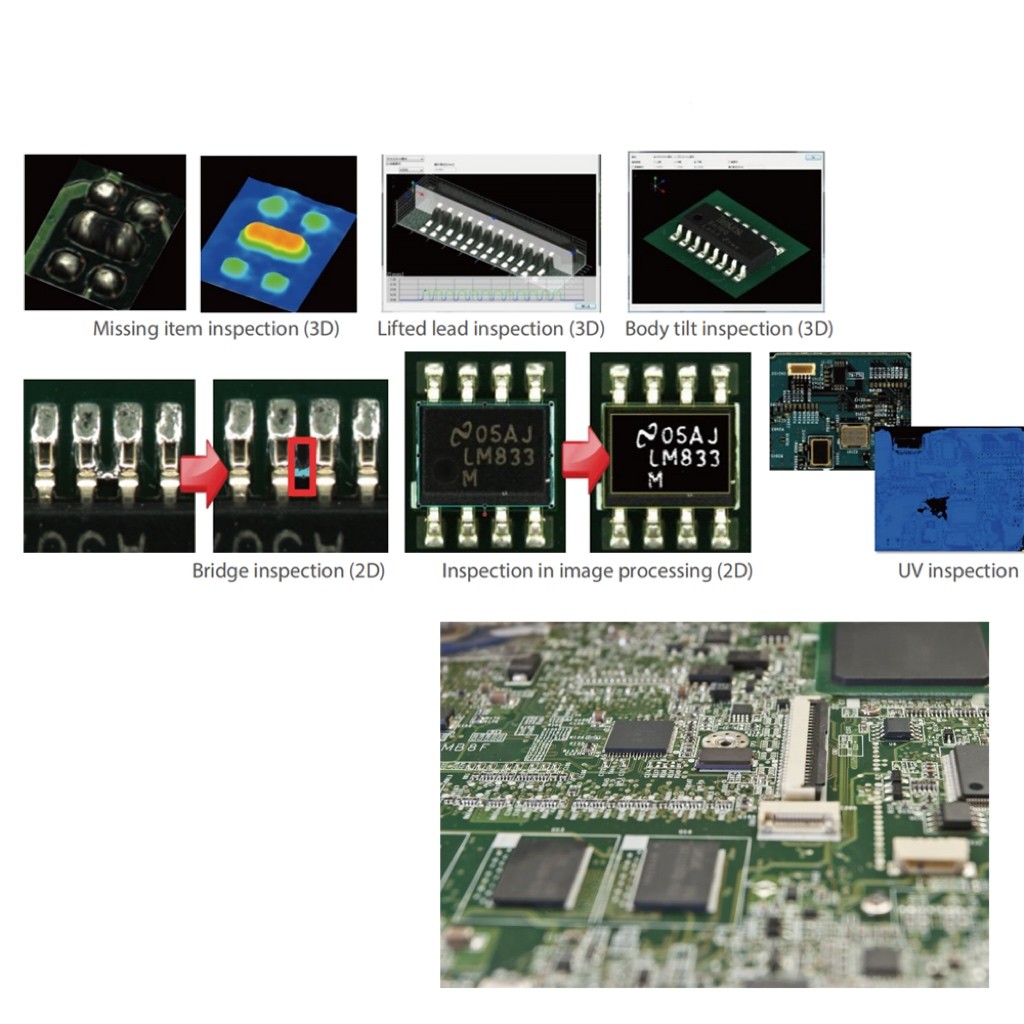

The lifecycle of PCB assembly involves several stages: design verification, component procurement, soldering techniques like SMT or through-hole methods, inspection processes, and finally testing for functionality before delivery. Each stage plays a vital role in ensuring that the assembled PCBs meet industry standards and customer expectations. By understanding this lifecycle better, businesses can optimize their operations to enhance efficiency while minimizing errors throughout the electronic PCB assembly process.

What is the Assembly of PCB?

In the world of electronics, understanding what is the assembly of PCB is crucial for anyone involved in manufacturing or designing electronic devices. Electronic PCB assembly refers to the process of connecting various electronic components onto a printed circuit board (PCB) to create functional devices. This intricate process transforms bare PCBs into fully operational circuits, ready for integration into a wide array of applications.

Defining PCB Assembly

PCB assembly encompasses all activities involved in attaching electronic components to a printed circuit board. This includes soldering components like resistors, capacitors, and integrated circuits onto the PCB surface, ensuring they are securely connected for optimal performance. The goal is to create a reliable and efficient electronic device that meets specific design requirements and quality standards.

Key Steps in the PCB Assembly Process

The journey from bare boards to finished products involves several key steps in the PCB assembly process. First, component placement occurs where automated machines accurately position components on the board according to design specifications. Next comes soldering—either through wave soldering or SMT (Surface Mount Technology)—which ensures robust electrical connections between components and the PCB itself. Finally, testing and inspection are conducted to verify functionality and adherence to quality standards before packaging for delivery.

Importance of Precision in Assemblies

Precision plays an indispensable role in electronic PCB assembly; even minor misalignments can lead to significant performance issues or failures in devices. Each component must be placed accurately and soldered correctly for reliable operation within various applications—from consumer electronics to industrial machinery. As technology advances, achieving higher precision becomes increasingly vital, making it essential for manufacturers to invest in state-of-the-art equipment and skilled technicians who understand what is SMT PCB assembly and its benefits.

Who is the Manufacturer of PCB Assembly in China?

When it comes to electronic PCB assembly, China stands out as a key player in the global market. The country is home to numerous manufacturers specializing in this field, offering a range of services from prototyping to mass production. Understanding who these manufacturers are can help businesses make informed decisions when seeking reliable partners for their PCB assembly needs.

Leading PCB Assembly Manufacturers

China boasts several leading PCB assembly manufacturers known for their quality and innovation. Companies like Jabil, Foxconn, and Wistron have established themselves as giants in the industry, providing comprehensive solutions that cover every aspect of electronic PCB assembly. These manufacturers leverage advanced technologies and efficient processes to ensure high-quality output while keeping costs competitive.

In addition to these well-known names, there are many smaller yet highly skilled manufacturers that specialize in niche markets or specific technologies such as SMT (Surface Mount Technology) PCB assembly. These companies often provide personalized service and flexibility that larger corporations might lack. As businesses look for partners in the realm of PCB assembly, exploring both large and small manufacturers can yield fruitful results.

Why Choose Chinese Manufacturers?

Choosing Chinese manufacturers for electronic PCB assembly offers numerous advantages that cannot be overlooked. First and foremost, cost efficiency is a significant factor; manufacturing in China often means lower labor costs without compromising quality standards. Additionally, the sheer scale of production capabilities allows for rapid turnaround times—an essential aspect when time-to-market is critical.

Moreover, many Chinese manufacturers have invested heavily in state-of-the-art technology and equipment, making them leaders in SMT PCB assembly techniques. This commitment to innovation ensures that they remain competitive on a global scale while meeting diverse customer requirements across various industries. Furthermore, language barriers are diminishing as many companies employ English-speaking staff who facilitate smoother communication with international clients.

Bensun Technology: A Reliable Partner

Among the myriad options available for those asking Who is the manufacturer of PCB assembly in China?, Bensun Technology emerges as a reliable partner worth considering. With years of experience under its belt, Bensun specializes in electronic PCB assembly with an emphasis on quality control and customer satisfaction. Their expertise spans various sectors including automotive electronics, consumer goods, and medical devices—making them a versatile choice for different business needs.

Bensun’s dedication to precision aligns perfectly with the importance of understanding what is the difference between PCB and PCB assembly; they ensure every component fits seamlessly into their assemblies while adhering to rigorous testing protocols before shipment. Additionally, their commitment to using cutting-edge SMT technology enhances performance reliability across all products manufactured under their supervision.

For businesses looking into collaborations or partnerships focused on high-quality electronic PCB assemblies, Bensun Technology stands out not just for its manufacturing capabilities but also its customer-centric approach aimed at fostering long-term relationships.

What is the Difference Between PCB and PCB Assembly?

When diving into the world of electronics, it's crucial to distinguish between a printed circuit board (PCB) and the electronic PCB assembly process. A PCB serves as the backbone of electronic devices, providing a platform for electrical connections between components. In contrast, PCB assembly refers to the intricate process where these components are attached to the PCB, transforming it into a functional unit ready for use.

Understanding PCB and PCB Assembly

To fully grasp what is the assembly of PCB, we need to start with its foundation: the printed circuit board itself. A PCB is essentially a flat board made from insulating material that has conductive pathways etched onto its surface, allowing electrical signals to flow between various components. On the other hand, electronic PCB assembly involves placing and soldering components such as resistors, capacitors, and integrated circuits onto this board—turning it from a mere substrate into an operational piece of technology.

Understanding this distinction is vital for anyone involved in electronics production or design. The processes are interconnected yet distinctly different; while PCBs can exist independently as bare boards, they require assembly to become functional assemblies used in everything from smartphones to industrial machinery. This highlights why knowing what is SMT PCB assembly or who is the manufacturer of PCB assembly in China can be essential knowledge for sourcing high-quality products.

Components of PCB Assembly

The heart of any electronic device lies within its components—the building blocks that make up an effective electronic PCB assembly. These include passive elements like resistors and capacitors alongside active elements such as microcontrollers and diodes that drive functionality within devices. Each component plays a pivotal role in ensuring that signals are processed correctly and efficiently.

Moreover, understanding these components helps in grasping how they interact during the assembly phase—something critical for manufacturers looking to optimize their production processes. Innovations in materials and designs have led to more compact assemblies without sacrificing performance levels; thus improving overall product reliability while reducing costs associated with larger traditional PCBs. In today's market landscape, knowing what makes up effective PCB assembly components can give businesses an edge over competitors.

Applications and Uses

The applications of PCBs extend far beyond just consumer electronics; they are integral across various industries including automotive, telecommunications, medical devices, and aerospace technologies among others. Each application requires specific considerations during both design and assembly phases—making it crucial for manufacturers to understand not only what is SMT PCB assembly but also how different assemblies meet unique industry standards.

In automotive systems alone, PCBs manage everything from engine control units (ECUs) to infotainment systems—all reliant on precise electronic PCB assemblies for optimal functionality under demanding conditions. Similarly, medical devices depend on reliable PCBs that must adhere strictly to safety regulations due to their life-saving roles; thus emphasizing why selecting reputable manufacturers becomes vital when considering who is the manufacturer of PCB assembly in China or elsewhere globally.

The versatility of PCBs means they will continue evolving with advancements in technology; hence understanding both their structure and function will remain paramount moving forward into future innovations within electronics manufacturing.

What is SMT PCB Assembly?

Surface Mount Technology (SMT) PCB assembly represents a pivotal advancement in the realm of electronic PCB assembly. This method involves mounting electronic components directly onto the surface of printed circuit boards, or PCBs, rather than inserting them through holes, as seen in traditional techniques. Understanding what SMT PCB assembly entails is crucial for those looking to delve deeper into the complexities of modern electronics manufacturing.

Definition of SMT PCB Assembly

SMT PCB assembly is defined by its innovative approach to placing components on PCBs, allowing for a more compact and efficient design. In this process, components are soldered onto the surface of the board using automated machines that ensure precision and speed. This technique is particularly advantageous in high-volume production where consistent quality and rapid turnaround are essential.

Benefits of SMT Technology

The benefits of SMT technology are numerous and impactful for manufacturers and end-users alike. Firstly, it allows for smaller component sizes, which leads to more compact designs and higher circuit density—perfect for today’s trend toward miniaturization in electronics. Additionally, SMT offers improved performance due to shorter electrical paths between components, leading to faster signal transmission and reduced noise levels in electronic circuits.

Moreover, using SMT can significantly lower production costs due to its compatibility with automated assembly processes that enhance efficiency while minimizing human error. By adopting this technology, manufacturers can produce reliable products that meet market demands swiftly.

Comparison with Other Assembly Techniques

When comparing SMT with other assembly techniques such as Through-Hole Technology (THT), several distinctions emerge that highlight its advantages in electronic PCB assembly. THT involves inserting components through holes drilled into the PCB and soldering them from below; while effective for certain applications, it often results in larger boards with less component density compared to SMT assemblies.

Furthermore, unlike THT which requires manual intervention during part placement and soldering processes, SMT leverages automation extensively—leading to higher throughput rates and consistency across batches. As industries evolve toward more sophisticated electronics designs requiring space efficiency without compromising performance, it’s clear why many manufacturers are gravitating towards SMT as their preferred method of PCB assembly.

PCB Assembly Components

When delving into electronic PCB assembly, understanding the components that make up the assembly is crucial. These components are not just random pieces; they play a significant role in determining how well the PCB functions in its intended application. From resistors to integrated circuits, every component has a purpose that contributes to the overall performance of the assembled board.

Types of Components Used in PCB Assembly

In electronic PCB assembly, various types of components come into play, each serving distinct functions. Commonly used components include resistors, capacitors, diodes, and transistors, alongside more complex elements like microcontrollers and sensors. Each type of component is carefully chosen based on its specifications and how it aligns with the design requirements of the PCB.

Additionally, surface mount technology (SMT) has introduced a new wave of components that are smaller and more efficient than their through-hole counterparts. The flexibility in choosing from a wide variety of components allows manufacturers to create tailored solutions for diverse applications. Understanding what these components are is essential when considering what is the assembly of PCB?

Role of Components in Functionality

The functionality of any electronic device hinges on its PCB assembly components working harmoniously together. Each component plays a critical role—resistors manage current flow, capacitors store energy temporarily, and microcontrollers process data inputs to produce outputs effectively. Without precise integration and high-quality parts during the electronic PCB assembly process, devices can malfunction or fail altogether.

Moreover, as technology advances, so does the complexity of these assemblies; hence ensuring that every component meets stringent quality standards becomes even more vital. The synergy between different types of components can significantly enhance performance while reducing power consumption—a key consideration in modern electronics design. This interplay raises an important question: What is the difference between PCB and PCB assembly?

Innovations in PCB Components

Innovation in PCB components continues to transform electronic manufacturing landscapes dramatically. New materials such as flexible substrates allow for bendable PCBs suited for wearables or compact devices—pushing boundaries previously thought impossible in traditional designs. Additionally, advancements like embedded passive components enable even more space-saving designs while enhancing functionality.

Manufacturers are also leveraging smart technologies for real-time monitoring and diagnostics within PCBs themselves—leading to smarter products that can self-adjust based on performance metrics collected during operation. As we look ahead at future trends within this field—including increased miniaturization—the importance placed on innovative component design will only grow stronger within electronic PCB assembly practices.

Conclusion

In the world of electronics, understanding electronic PCB assembly is crucial for anyone involved in product development or manufacturing. The assembly process involves several key steps that transform a bare PCB into a fully functional electronic device. By grasping the intricacies of what is the assembly of PCB, manufacturers can ensure higher quality products and minimize errors.

Key Takeaways on Electronic PCB Assembly

Electronic PCB assembly is a multi-faceted process that combines precision engineering with innovative technology. It encompasses everything from component placement to soldering and testing, all of which are essential to creating reliable electronic devices. Recognizing who is the manufacturer of PCB assembly in China can lead to fruitful partnerships, as these manufacturers often provide cost-effective solutions without compromising quality.

Future Trends in PCB Assembly Technologies

As technology advances, so do the methods and materials used in electronic PCB assembly. Emerging trends such as automation, artificial intelligence, and advanced materials are set to revolutionize how PCBs are assembled. Additionally, understanding what is SMT PCB assembly will become increasingly important as this method continues to gain traction due to its efficiency and ability to accommodate complex designs.

Collaborating with Bensun Technology for Success

Choosing the right partner for your electronic PCB assembly needs can make all the difference in achieving your project goals. Bensun Technology stands out among manufacturers by offering expertise in both traditional and modern techniques while ensuring high standards of quality control throughout the process. By collaborating with Bensun Technology, businesses can leverage their knowledge about what is the difference between PCB and PCB assembly, ensuring optimal results tailored to specific applications.