Introduction

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) has become a cornerstone for efficient production. The importance of SMT technology cannot be overstated, as it allows for high-density circuit board assembly and improved reliability in electronic devices. Among the various tools that facilitate this process, the Juki SMT pick and place machine stands out as a leader in precision and performance.

The Importance of SMT Technology

SMT technology revolutionizes how components are mounted onto circuit boards, significantly enhancing production speed and reducing manual labor. By utilizing automated systems like pick and place machines, manufacturers can achieve greater accuracy and consistency in their assemblies. This shift not only optimizes workflow but also drives down costs—making it an essential aspect of modern electronics manufacturing.

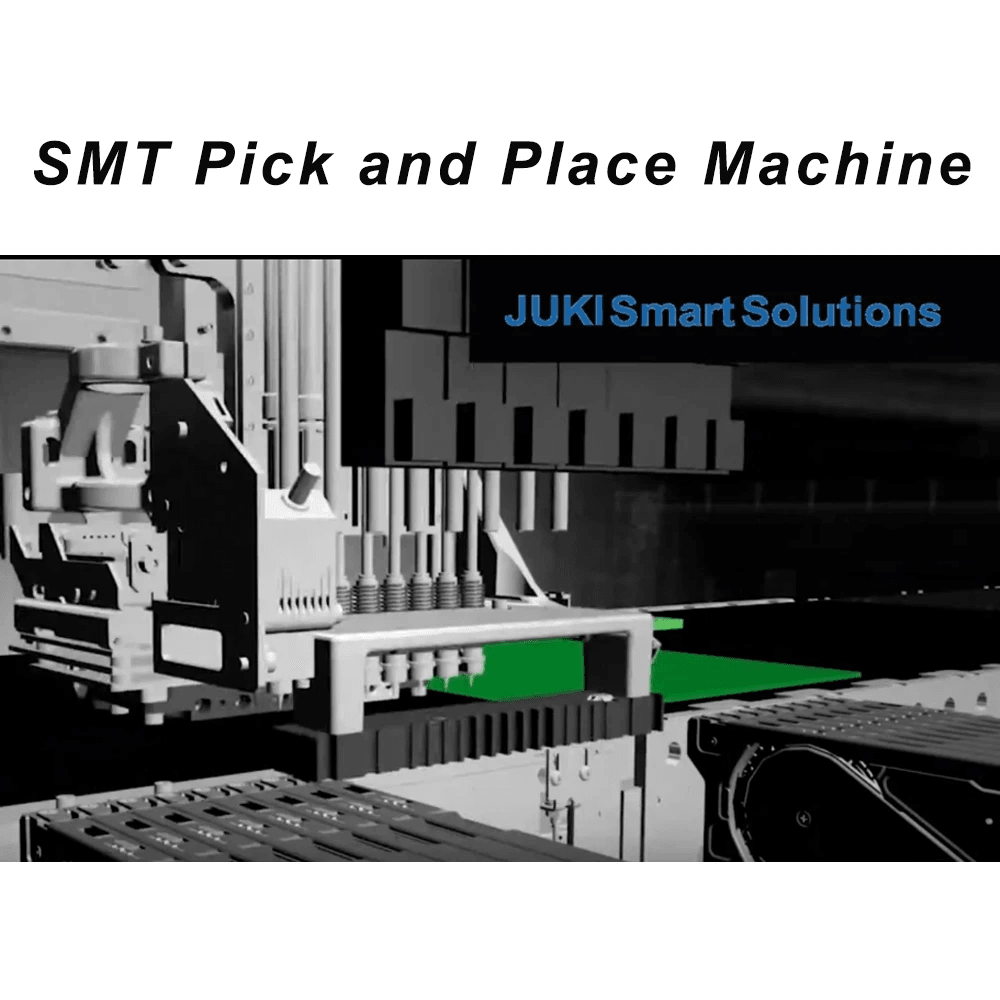

Understanding Pick and Place Machines

So, what is pick and place in SMT? At its core, this technology involves robotic arms that pick components from feeders and place them onto printed circuit boards (PCBs) with remarkable precision. These machines are critical for automating the assembly process, ensuring that each component is positioned correctly to meet stringent quality standards while minimizing human error.

Why Juki Stands Out

Known for their reliability and advanced features, Juki's SMT pick and place machines offer unparalleled performance tailored to meet diverse production needs. With competitive pricing options such as the Juki SMT pick and place machine price being accessible to various budgets, investing in a Juki machine is a smart choice for businesses looking to enhance efficiency without compromising on quality.

What is Pick and Place in SMT?

In the world of Surface Mount Technology (SMT), the term pick and place refers to a highly efficient automated process that revolutionizes how electronic components are assembled onto circuit boards. This technology utilizes sophisticated machines to accurately pick up components from a feeder and place them onto designated spots on the PCB, ensuring precision and speed that manual assembly simply cannot match. Understanding this process is crucial for manufacturers looking to enhance their production capabilities and maintain competitive advantages in an increasingly fast-paced market.

Defining the Technology

At its core, pick and place technology involves a series of mechanical arms equipped with suction cups or grippers that can handle various electronic components, from tiny resistors to larger capacitors. The Juki SMT pick and place machine exemplifies this technology, utilizing advanced vision systems to identify component orientation and placement accuracy. This automation not only speeds up production but also minimizes human error, making it a preferred choice for manufacturers aiming for high-quality results.

Key Benefits for Manufacturers

Manufacturers who embrace pick and place machines like the Juki SMT pick and place machine experience numerous benefits that significantly enhance their operations. For starters, these machines drastically reduce assembly time compared to traditional methods, allowing companies to ramp up production without compromising quality. Additionally, the precision offered by these machines leads to fewer defects in finished products, which ultimately translates into lower costs associated with rework or scrap—making it a savvy investment for any manufacturer.

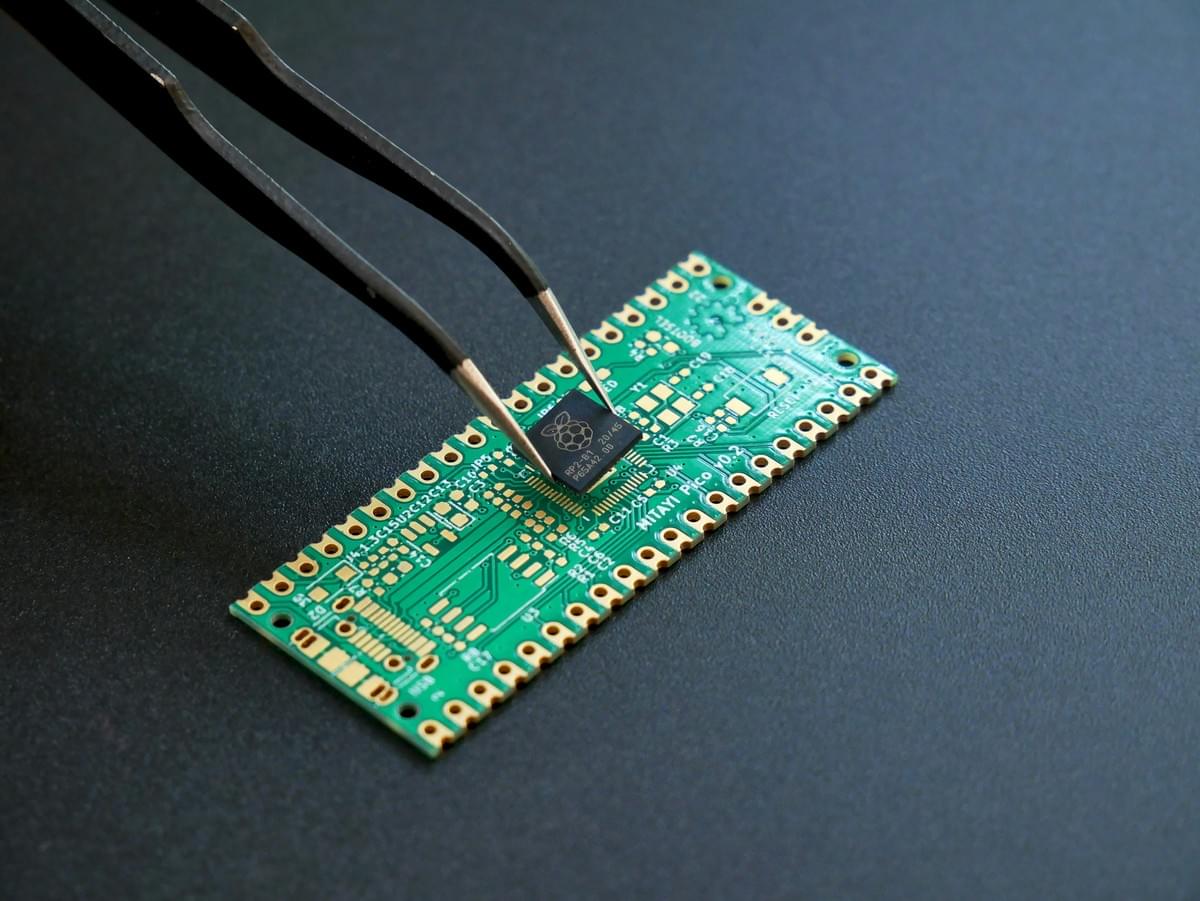

Comparison with Manual Assembly

When comparing pick and place technology with manual assembly processes, the differences become starkly evident. Manual assembly relies heavily on skilled labor, which can introduce variability in quality due to human error or fatigue over long shifts; conversely, machines like the Juki SMT pick and place machine provide consistent performance regardless of workload duration. Furthermore, while manual assembly may seem cost-effective initially due to lower upfront costs, investing in automated systems typically yields better long-term ROI by increasing throughput and reducing labor costs over time.

Leading Brands in the SMT Machine Market

In the competitive world of Surface Mount Technology (SMT), several brands have carved out a significant presence. Each brand brings its unique flair to the table, but few stand out quite like Juki. Understanding what makes Juki a leader in this field can help manufacturers make informed decisions about their SMT needs.

Overview of Top Brands

When discussing the top 10 popular SMT machine brands, several names frequently come up: Panasonic, Yamaha, ASM Assembly Systems, and of course, Juki. These companies have established themselves as reliable providers of advanced pick and place machines that cater to various manufacturing needs. Each brand offers distinct features and capabilities that appeal to different segments of the market.

Juki’s Competitive Edge

So, what gives Juki its competitive edge? Primarily, it’s their commitment to innovation and quality in their SMT pick and place machines. Known for reliability and precision, Juki's products consistently outperform many competitors in both speed and accuracy—traits essential for high-volume production environments.

What Sets Juki Apart?

What truly sets Juki apart from other brands is not just their state-of-the-art technology but also their user-friendly approach. The intuitive design of the Juki SMT pick and place machine allows operators to easily navigate its features without extensive training or hassle. Moreover, when you look at the overall value proposition—including factors like performance versus cost—Juki's price point remains competitive while still delivering exceptional quality compared to other leading brands.

The Advantages of Choosing Juki

When it comes to SMT technology, choosing the right pick and place machine can make all the difference in production efficiency and quality. Juki has established itself as a leader in this space, particularly with its renowned Juki SMT pick and place machine. By examining the advantages of selecting Juki for your manufacturing needs, you can see why it stands out among the top 10 popular SMT machine brands.

Reliability and Precision

Reliability is a cornerstone of Juki's design philosophy, ensuring that their SMT pick and place machines consistently deliver high-quality results. With advanced technology integrated into every unit, you can expect remarkable precision in component placement, which is crucial for minimizing defects and maximizing yield. When manufacturers ask What is pick and place in SMT? they quickly learn that reliability directly influences productivity, making Juki an ideal choice.

Moreover, Juki's commitment to excellence means that their machines are built to last, reducing downtime significantly compared to lesser brands. This durability translates into fewer interruptions during production runs—a significant advantage when considering the overall cost-effectiveness of a Juki SMT pick and place machine. Ultimately, investing in a reliable machine pays off by enhancing operational efficiency.

Advanced Features and Capabilities

What sets the Juki SMT pick and place machine apart from competitors is its suite of advanced features designed to meet modern manufacturing demands. These machines come equipped with cutting-edge technology such as vision systems for precise alignment and automated calibration processes that simplify setup times significantly. This combination allows manufacturers to adapt quickly to changing production requirements without sacrificing quality.

Additionally, Juki’s machines support various component types—from tiny chips to larger packages—making them versatile enough for diverse applications across industries. The ability to handle different components efficiently means reduced changeover times between projects, further enhancing productivity levels on your production line. With these advanced capabilities at your disposal, it's easy to see why many businesses are turning towards Juki when searching for who makes pick and place machines.

User-Friendly Interface

One of the standout features of the Juki SMT pick and place machine is its user-friendly interface that simplifies operation even for those new to automated assembly processes. Intuitive controls allow operators to navigate through settings effortlessly while providing real-time feedback on performance metrics—essential information for maintaining optimal workflow efficiency. This ease of use minimizes training time for staff while maximizing output from day one.

Furthermore, many users have reported that transitioning from manual assembly methods becomes seamless with the straightforward design of Juki’s equipment; this helps answer questions like What is the top 10 popular SMT machine brand? as it positions itself favorably among competitors known for complex interfaces or steep learning curves. By focusing on user experience alongside technological advancements, choosing a Juki SMT pick and place machine not only boosts productivity but also enhances employee satisfaction.

Cost Considerations: Juki Pick and Place Machine Price

When it comes to investing in a Juki SMT pick and place machine, understanding the price dynamics is essential for any manufacturer looking to enhance their production line. The cost of a Juki SMT pick and place machine can vary widely based on features, capabilities, and the specific model chosen. However, what remains consistent is the value that these machines bring in terms of efficiency and precision.

Evaluating Juki SMT Machine Price

Evaluating the price of a Juki SMT pick and place machine involves more than just looking at the sticker price; it’s about understanding what you get for your investment. Generally, prices can range from mid-tier to high-end depending on specifications like speed, component handling capabilities, and automation level. For manufacturers serious about quality control and production efficiency, investing in a reliable Juki SMT machine often pays off significantly over time.

Long-Term Value and ROI

The long-term value associated with a Juki pick and place machine is where many manufacturers find their peace of mind. While the initial investment might seem steep compared to other options in the market—especially when considering popular brands like Panasonic or Yamaha—the return on investment (ROI) can be substantial. With lower operational costs due to reduced labor needs, increased throughput rates, and fewer errors during assembly processes, businesses often recoup their costs much faster than anticipated.

Financing Options for Businesses

For those concerned about upfront costs but eager to tap into the benefits of a Juki SMT pick and place machine, various financing options are available. Many suppliers offer leasing programs or installment plans that make it easier for businesses to integrate this technology without breaking the bank upfront. Additionally, exploring grants or financial incentives aimed at enhancing manufacturing capabilities can further ease financial burdens while enabling companies to stay competitive.

Bensun Technology: Your Partner in SMT Solutions

In the ever-evolving world of Surface Mount Technology (SMT), having the right partner can make all the difference. Bensun Technology positions itself as a reliable ally for businesses looking to enhance their production capabilities, particularly with Juki SMT pick and place machines. With a comprehensive suite of services, tailored solutions, and steadfast support, Bensun ensures that manufacturers can optimize their operations effectively.

Comprehensive Services Offered

Bensun Technology offers a wide range of services designed to meet the specific needs of SMT manufacturers. From initial consultations to after-sales support, Bensun is committed to helping clients navigate the complexities of SMT processes. Their expertise extends to training on Juki SMT pick and place machines, ensuring users maximize efficiency and productivity with every assembly line.

Additionally, Bensun provides maintenance services that keep your Juki pick and place machine running smoothly over time. This proactive approach not only minimizes downtime but also enhances overall operational performance. By choosing Bensun as your partner, you gain access to a wealth of knowledge that helps streamline your manufacturing processes.

Tailored Production Line Solutions

Understanding that every business has unique requirements, Bensun Technology specializes in creating customized production line solutions that incorporate Juki’s advanced technology. Whether you're asking What is pick and place in SMT? or exploring how it fits into your operation, Bensun crafts strategies tailored specifically for you. This personalized approach ensures optimal integration of Juki's equipment into existing workflows.

Their team works closely with clients to assess current setups and recommend enhancements that align with industry best practices. By leveraging their extensive experience in working with various brands—including insights from the top 10 popular SMT machine brands—Bensun can deliver solutions that not only boost productivity but also reduce costs associated with inefficiencies.

Quality Control and Support

When investing in equipment like the Juki SMT pick and place machine, quality control becomes paramount for maintaining high production standards. Bensun Technology emphasizes rigorous quality assurance protocols throughout its service offerings to ensure every component meets industry specifications before it reaches your facility. This commitment helps businesses avoid costly errors down the line.

Support doesn't end at installation; ongoing assistance is crucial for navigating challenges as they arise during production runs using Juki’s advanced machinery. With dedicated customer service representatives ready to assist at any moment, clients can focus on what they do best—manufacturing high-quality products without worrying about equipment failures or operational hiccups.

In conclusion, partnering with Bensun Technology means having a reliable supporter who understands both the technicalities of Juki's offerings and the broader landscape of SMT manufacturing challenges—making it easier for businesses to thrive in this competitive market.

Conclusion

In the rapidly evolving landscape of surface mount technology (SMT), Juki stands as a beacon of innovation and reliability. The future of SMT with Juki is bright, as their pick and place machines continue to push the boundaries of efficiency and precision. With advancements in automation and smart technology, Juki's SMT solutions are set to redefine manufacturing standards.

The Future of SMT with Juki

Juki’s commitment to innovation ensures that their SMT pick and place machines will remain at the forefront of technology for years to come. As manufacturers seek greater efficiency, Juki’s machines are designed to adapt, incorporating features that enhance productivity while reducing downtime. This adaptability positions Juki not just as a manufacturer but as a partner in navigating the complexities of modern production.

Making an Informed Investment Decision

When considering a purchase, understanding the **Juki SMT pick and place machine price** is crucial for any business looking to invest wisely. Evaluating costs involves not only the initial price tag but also long-term value and return on investment (ROI). By weighing these factors carefully, businesses can make informed decisions that align with their operational goals while maximizing profitability.

Enhancing Efficiency with Bensun Technology

Bensun Technology emerges as an invaluable ally for companies seeking to optimize their production lines featuring **Juki SMT pick and place machines**. With tailored solutions that address specific needs, Bensun ensures that clients leverage every advantage offered by advanced machinery like those from Juki. Their commitment to quality control and support means businesses can focus on growth while trusting in their strategic partner.