Introduction

In the realm of electronics, understanding how PCBs are made is crucial for anyone looking to delve into the world of circuit boards. Printed Circuit Boards (PCBs) serve as the backbone of modern electronic devices, connecting various components and facilitating their functions. This PCB introduction sets the stage for exploring the intricate processes involved in PCB manufacturing, which are heavily reliant on quality manufacturing equipment.

Understanding PCB Fundamentals

At its core, a PCB is a flat board that electrically connects and supports electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. The significance of PCBs cannot be overstated; they are integral to almost every electronic device we use today, from smartphones to home appliances. A solid grasp of PCB fundamentals not only aids in appreciating their role but also enhances one's ability to navigate complex topics like the PCB manufacturing equipment list and advanced techniques.

Importance of Quality Manufacturing Equipment

The quality of equipment used in PCB production directly impacts the reliability and performance of the final product. Investing in top-notch manufacturing tools ensures precision during fabrication and assembly processes, ultimately leading to superior circuit board functionality. Whether you’re following a high-speed PCB design guide or diving into a detailed PCB design tutorial, having reliable equipment at your disposal is essential for achieving optimal results.

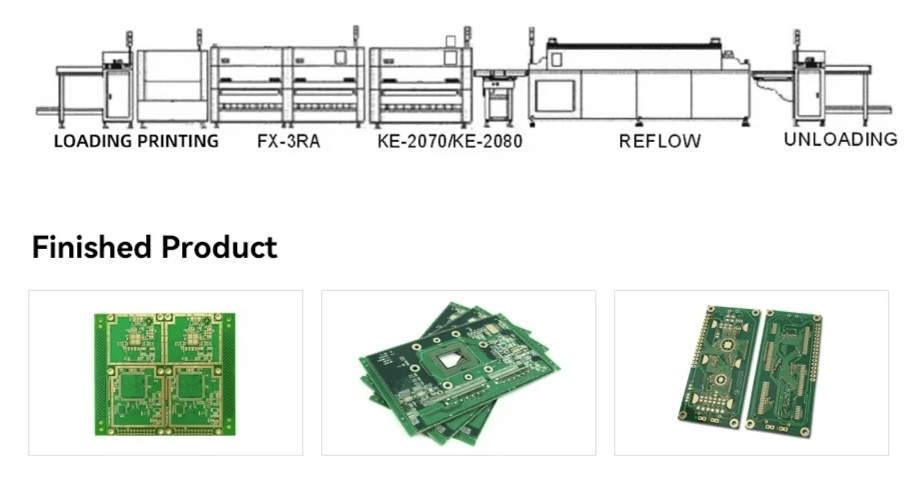

Overview of Modern PCB Manufacturing Techniques

Modern techniques for producing PCBs have evolved significantly over the years, incorporating innovative technologies that enhance efficiency and accuracy. From automated assembly processes to advanced printing methods, these techniques streamline production while maintaining high standards of quality control. As we explore how PCBs are made through these contemporary methods, it becomes clear that understanding these advancements is key to staying competitive in an ever-evolving industry.

PCB Manufacturing Equipment List

When it comes to how PCBs are made, the right equipment can make all the difference. A comprehensive PCB manufacturing equipment list is essential for any facility looking to optimize production and maintain quality. From design to assembly, each stage requires specific tools that cater to the intricate needs of circuit board creation.

Essential Tools for PCB Production

In any PCB introduction, one must highlight the essential tools that lay the foundation for successful production. At the core of this process are tools like photoplotters, etchers, and laminators, which are vital for transferring designs onto substrates and creating precise patterns. Additionally, inspection systems such as AOI (Automated Optical Inspection) ensure that every circuit board meets stringent quality standards before moving forward in the production line.

The high-speed PCB design guide emphasizes not only efficiency but also accuracy in using these tools. For example, a well-calibrated etcher can significantly reduce waste material while ensuring that traces remain intact during processing. Thus, investing in high-quality manufacturing equipment is crucial for maintaining a competitive edge in a rapidly evolving industry.

Analyzing Different Equipment Types

Diving deeper into our PCB manufacturing equipment list reveals a variety of machines designed for specific tasks within the fabrication process. Each type of equipment serves a unique purpose: from drilling machines that create holes for components to soldering stations that ensure strong connections between parts on the circuit board. Understanding these differences is key when considering how PCBs are made efficiently.

Moreover, advanced PCB equipment has taken center stage with innovations such as laser drilling and automated pick-and-place machines that enhance speed and precision in production lines. These technologies not only improve output but also allow manufacturers to tackle complex designs typically found in modern electronics—think smart devices or IoT applications! As we analyze different types of equipment, it becomes clear that choosing the right mix is vital for achieving both quality and productivity.

Innovative Technologies Transforming PCB Production

The landscape of PCB manufacturing is continuously evolving thanks to innovative technologies transforming how PCBs are made today. Techniques like additive manufacturing (3D printing) have begun making waves by allowing designers more freedom in creating complex geometries without traditional constraints associated with subtractive methods. This shift opens up new possibilities within our high-speed PCB design guide while also pushing boundaries on what’s achievable with circuit boards.

Furthermore, software solutions play an integral role in optimizing processes; simulations can predict performance issues before physical prototypes are even created! Coupled with advancements like smart factories where machinery communicates seamlessly via IoT networks—manufacturers can now achieve unprecedented levels of efficiency and control over their production lines. In summary, embracing these innovative technologies not only enhances capabilities but ensures a robust future for those involved in PCB fabrication.

High-Speed PCB Design Guide

In the fast-paced world of electronics, the speed at which PCBs are designed and manufactured can make or break a project. Understanding how PCBs are made is crucial for engineers aiming to shorten production timelines while maintaining quality. This section dives into the importance of speed in manufacturing, software solutions for fast PCB layouts, and how integrating equipment can streamline the design process.

Importance of Speed in Manufacturing

Speed in manufacturing is not merely a luxury; it’s a necessity in today’s competitive market. The quicker you can get your circuit board from design to production, the faster you can respond to market demands and customer needs. Moreover, rapid prototyping allows for quicker iterations and testing phases, ultimately leading to better products that meet evolving standards.

When considering your PCB manufacturing equipment list, it's essential to prioritize tools that enhance speed without sacrificing quality. Advanced PCB equipment plays a pivotal role here by automating repetitive tasks and minimizing human error during the design phase. In this high-speed environment, efficiency becomes synonymous with innovation as companies strive to keep pace with rapid technological advancements.

Software Solutions for Fast PCB Layouts

To achieve high-speed designs effectively, leveraging software solutions tailored for quick PCB layouts is vital. Modern PCB design tools offer features like automated routing and real-time simulation which significantly reduce time spent on manual adjustments. These innovations transform traditional workflows into streamlined processes that can handle complex designs with ease.

A comprehensive PCB design tutorial often highlights popular software options such as Altium Designer or Eagle CAD that cater specifically to high-speed requirements. These programs provide intuitive interfaces along with powerful capabilities that help engineers visualize their designs better while speeding up the overall layout process. By utilizing these advanced tools, designers can ensure their circuit boards are optimized for performance right from the start.

Integrating Equipment for Efficient Design

Integrating various pieces of advanced PCB equipment into your workflow not only enhances efficiency but also fosters collaboration among teams involved in different stages of production. For example, connecting CAD software directly with fabrication machines allows for seamless data transfer—eliminating potential errors associated with manual entry and ensuring accuracy in how PCBs are made from start to finish.

Furthermore, this integration facilitates real-time updates on project status across all departments involved in manufacturing processes—enhancing communication and reducing lead times dramatically. As we explore more about how PCBs are made through innovative methods and technologies, it becomes clear that choosing the right combination of equipment is crucial for achieving optimal results in both design speed and product quality.

The PCB Fabrication Process

The journey of creating a printed circuit board (PCB) is a fascinating blend of art and science, where precision meets innovation. Understanding how PCBs are made is essential for anyone involved in electronics, from hobbyists to industry professionals. This section will delve into the step-by-step process, the advanced PCB equipment used, and the quality control measures that ensure a reliable product.

Step-by-Step Guide on How PCBs Are Made

The PCB fabrication process begins with designing the circuit board layout, often guided by a comprehensive PCB design tutorial or software tools from our PCB manufacturing equipment list. Once the design is finalized, it’s translated into a photomask that defines where copper will be etched away during manufacturing. Next comes substrate preparation, where materials like FR-4 are cut and cleaned to create a solid foundation for your circuit board.

After substrate preparation, layers of copper foil are laminated onto the material using heat and pressure—this is crucial for ensuring strong adhesion and reliability in how PCBs are made. The next step involves etching away unwanted copper using chemical solutions or laser technology to reveal the desired circuitry pattern. Finally, drilling holes for components and plating them with gold or other conductive materials ensures your PCB can support various electronic parts effectively.

Role of Advanced PCB Equipment in Fabrication

Advanced PCB equipment plays an indispensable role throughout the fabrication process by enhancing efficiency and precision at each stage of production. High-speed drills allow for accurate hole placement while minimizing damage to the substrate material—a critical factor in how PCBs are made successfully without compromising quality. Additionally, automated etching machines ensure uniform removal of copper layers, which contributes significantly to achieving intricate designs outlined in your high-speed PCB design guide.

Furthermore, modern laminators provide consistent pressure and temperature control during layer bonding—key aspects that directly influence durability and performance of circuit boards. Inspection systems equipped with cameras detect defects early on in production; this proactive approach minimizes waste while maintaining high standards across all manufactured units. Thus, investing in advanced equipment not only streamlines processes but also enhances overall product reliability.

Quality Control Measures in Each Stage

Quality control is paramount throughout every stage of PCB fabrication because even minor errors can lead to significant failures down the line—nobody wants their circuit board to short-circuit! Inspections typically commence with visual checks after each major step: verifying alignment during lamination or ensuring clean cuts post-etching helps catch issues before they escalate further into production cycles. Implementing rigorous testing protocols like electrical tests ensures functionality aligns perfectly with design specifications outlined earlier.

Moreover, employing statistical process control techniques allows manufacturers to monitor processes continuously; this data-driven approach identifies deviations from expected outcomes quickly so corrective measures can be implemented immediately—an essential aspect when considering how PCBs are made efficiently over time! Finally, comprehensive final inspections guarantee that only top-quality products leave the facility ready for assembly or integration into larger systems.

Circuit Board Assembly Techniques

When it comes to circuit board assembly, the methods employed can significantly impact the overall quality and efficiency of PCB production. Understanding how PCBs are made is crucial for manufacturers looking to optimize their processes. This section will delve into various assembly techniques, comparing their benefits and drawbacks while highlighting essential PCB manufacturing equipment.

Comparison of Assembly Methods

There are several methods for assembling circuit boards, each with its unique advantages and challenges. The most common techniques include surface mount technology (SMT), through-hole technology (THT), and mixed technology, which combines both SMT and THT. In our PCB design tutorial, we'll explore how these methods affect not just the assembly process but also the overall design considerations in high-speed PCB design guides.

Automated vs. Manual Assembly Options

When choosing between automated and manual assembly options, it's essential to consider factors like production volume and complexity of designs. Automated assembly can offer speed and precision, making it ideal for high-volume runs where consistency is key; however, manual assembly may be more suitable for low-volume or specialized projects that require a human touch. Ultimately, understanding how PCBs are made through these different approaches will help you make informed decisions about your PCB manufacturing equipment list.

Choosing the Right Equipment for Your Needs

Selecting the right equipment is paramount in achieving optimal results in circuit board assembly techniques. Advanced PCB equipment can streamline processes while ensuring quality output; therefore, investing in top-notch machinery can pay dividends in efficiency and reliability over time. When evaluating your options, consider not only your current needs but also future scalability as you continue to refine your high-speed PCB design guide.

Contract Manufacturing Services

In the ever-evolving landscape of electronics, contract manufacturing services have become a pivotal solution for companies looking to streamline their PCB production processes. By leveraging specialized expertise and advanced PCB equipment, businesses can focus on core competencies while outsourcing the complexities of how PCBs are made. This synergy not only enhances efficiency but also ensures high-quality outcomes through collaboration with established manufacturers.

Benefits of PCB Contract Manufacturing

One of the primary benefits of PCB contract manufacturing is cost-effectiveness. By utilizing an established PCB manufacturing equipment list, companies can save on initial capital investments and operational costs associated with in-house production. Additionally, contract manufacturers often have access to cutting-edge technologies and skilled labor, which significantly boosts production speed—a crucial factor highlighted in any high-speed PCB design guide.

Another advantage is scalability; businesses can quickly adjust production volumes based on demand without the hassle of managing inventory or workforce fluctuations. This flexibility is particularly beneficial for startups or smaller firms that may not have the resources to maintain large-scale operations year-round. Furthermore, by partnering with experts in the field, companies can ensure that they are following best practices outlined in various PCB design tutorials, leading to higher quality circuit boards.

Lastly, focusing on core business activities while outsourcing manufacturing allows companies to innovate and improve product offerings continually. With a reliable partner handling the intricacies of how PCBs are made, organizations can dedicate more time to research and development efforts that drive growth and market competitiveness.

Bensun Technology's Role in PCB Production

Bensun Technology has carved out a niche as a leading provider in the realm of contract manufacturing services for PCBs. Their commitment to quality assurance and utilization of advanced PCB equipment sets them apart from competitors in this crowded marketplace. With an extensive PCB manufacturing equipment list at their disposal, they are well-equipped to handle diverse project requirements ranging from prototype development to mass production.

The company places significant emphasis on integrating innovative technologies into their processes, ensuring that clients receive products that meet modern standards for performance and reliability. By applying principles from high-speed PCB design guides throughout their operations, Bensun Technology maximizes efficiency without compromising quality during fabrication or assembly stages.

Moreover, Bensun Technology prides itself on maintaining transparent communication with clients throughout every stage of production—an essential factor when selecting a partner for your circuit board needs. Their expertise not only helps navigate potential pitfalls but also fosters collaborative solutions tailored specifically for each project's unique challenges.

Key Considerations When Selecting a Partner

Choosing the right contract manufacturer is crucial for ensuring your project’s success; therefore, there are several key considerations you should keep in mind during your selection process. First and foremost is assessing their experience level—look for partners who have demonstrated proficiency in how PCBs are made across various industries similar to yours. This experience often translates into valuable insights regarding best practices and innovative techniques that could enhance your product's performance.

Next up is evaluating their technological capabilities; ensure they possess an up-to-date PCB manufacturing equipment list that aligns with your project requirements—especially if you’re aiming for high-speed designs or complex layouts outlined in popular PCB design tutorials available today. A manufacturer equipped with advanced tools will be better positioned to meet tight deadlines while maintaining exceptional quality standards.

Finally, consider customer support as another vital element; effective communication channels can make all the difference when it comes to navigating challenges during production cycles or implementing last-minute changes efficiently without derailing timelines or budgets associated with circuit board assembly projects.

Conclusion

In summary, understanding how PCBs are made is crucial for anyone involved in electronics, from hobbyists to professionals. The PCB manufacturing equipment list provides a roadmap for the essential tools required to ensure quality and efficiency in production. Furthermore, the High-speed PCB design guide highlights the importance of integrating advanced technologies that can streamline processes and improve overall output.

Recap of PCB Manufacturing Essentials

Throughout this discussion, we’ve explored the fundamental aspects of PCB manufacturing, from the initial design phase to the final assembly techniques. We emphasized how critical it is to leverage an appropriate PCB manufacturing equipment list that includes both traditional tools and innovative technologies. Additionally, we delved into various methods of circuit board assembly, reinforcing that a well-rounded understanding of how PCBs are made can significantly impact production quality and speed.

The Future of PCB Production and Equipment

Looking ahead, the future of PCB production is poised for exciting advancements driven by technological innovations and increasing demands for miniaturization and complexity in electronic devices. With emerging trends such as automation and smart manufacturing techniques reshaping the landscape, staying updated on advanced PCB equipment will be vital for manufacturers aiming to remain competitive. As we continue to refine our approaches through resources like a comprehensive PCB design tutorial or high-speed design guides, we can expect even greater efficiencies in how PCBs are made.

Final Thoughts on Choosing Quality Equipment

Choosing quality equipment is not just about immediate needs; it's an investment in long-term success within the ever-evolving electronics industry. By carefully evaluating your options based on your specific requirements—whether you’re focusing on speed with a high-speed PCB design guide or exploring advanced technologies—you set yourself up for sustainable growth. Remember that every element in your production line plays a role in determining not only how PCBs are made but also their performance in real-world applications.